Production Area

Quality Control and Laboratory

Quality Control and Laboratory Block Production

Block Production Forging Workshop

Forging Workshop Heat Treatment

Heat Treatment

Magnetic Fracture Control

Magnetic Fracture Control Sandblast Area

Sandblast Area Raw Material Stock Area

Raw Material Stock Area Stok Area For Shipment

Stok Area For Shipment

Other titles of our site:

www.balkancelik.com

www.balkandovme.com

www.balkancelikdovme.com

www.balkancelikdovme.com.tr

www.balkansteelforge.com

www.balkanforge.com

www.balkanstahlschmiede.com

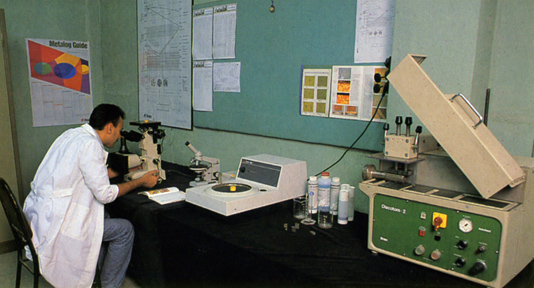

Quality Control and Laboratory

The activities of Quality Assurance Department is directed to preselected targets in order to achieve quality improvement and reliability. We would like to draw your kind attention to these aimed targets:

- Determination of acceptable quality: The material and specification standards are released for the determination of the acceptable quality product quality.

- Reliability on Quality Assurance: This goal is achieved by starting with are in the various production steps are closely and carefully controlled by Q.C. rawing inspectors. By this practice, the acceptable quality level is maintained resulting acceptable finished products.

- Quality Assurance: This goal is achieved by starting with the incoming raw material inspections and finalizing with the checking on the finished parts. Incoming material inspection, final checking sections and material testing laboratory are responsible units in this respect.

Incoming raw materials are carefully analyzed for the conformity of chemical properties and also mechanical checks are carried out for acceptance of the lot. Perishable tools like, drills, reamers, Jigs and fixtures are subject to incoming inspection.

In the manifacturing areas, parts are inspected by the use of up to-date measuring and crack detection devices and equipments.

- Reliability on Quality Assurance: This goal is achieved by starting with are in the various production steps are closely and carefully controlled by Q.C. rawing inspectors. By this practice, the acceptable quality level is maintained resulting acceptable finished products.

- Quality Assurance: This goal is achieved by starting with the incoming raw material inspections and finalizing with the checking on the finished parts. Incoming material inspection, final checking sections and material testing laboratory are responsible units in this respect.

Incoming raw materials are carefully analyzed for the conformity of chemical properties and also mechanical checks are carried out for acceptance of the lot. Perishable tools like, drills, reamers, Jigs and fixtures are subject to incoming inspection.

In the manifacturing areas, parts are inspected by the use of up to-date measuring and crack detection devices and equipments.